Waste water shut off valves can prove to be essential for a safe and precise functioning of your industry, like a water sewerage plant or a water recycling or treatment facility. Why? Let us tell you.

Waste Water Shut Off Valves – What are they?

Waste water shut off valves mostly have a constant flow of water flowing through them at all times. The valves are generally used to shut off the water supply due to routine inspections or in an event of an emergency in the facility. A waste water shut off valve is usually installed in water treatment industries for sewage and sludge, and they deal with fluid transference at a small or a large scale.

Some facilities have a water meter, which is located on the inside. However, it can also be located on the outside, in a pit underground or out of the way and at a distance from the property lines. Waste water shut off valves are generally operated with a round wheel or lever handle. Although, waste water shut off valves can also be operated pneumatically using air.

The air operated pinch valve is being used more and more as a waste water shut off valve.

Comparing the Types of Waste Water Shut Off Valves

- Ball Valves & Butterfly Valves

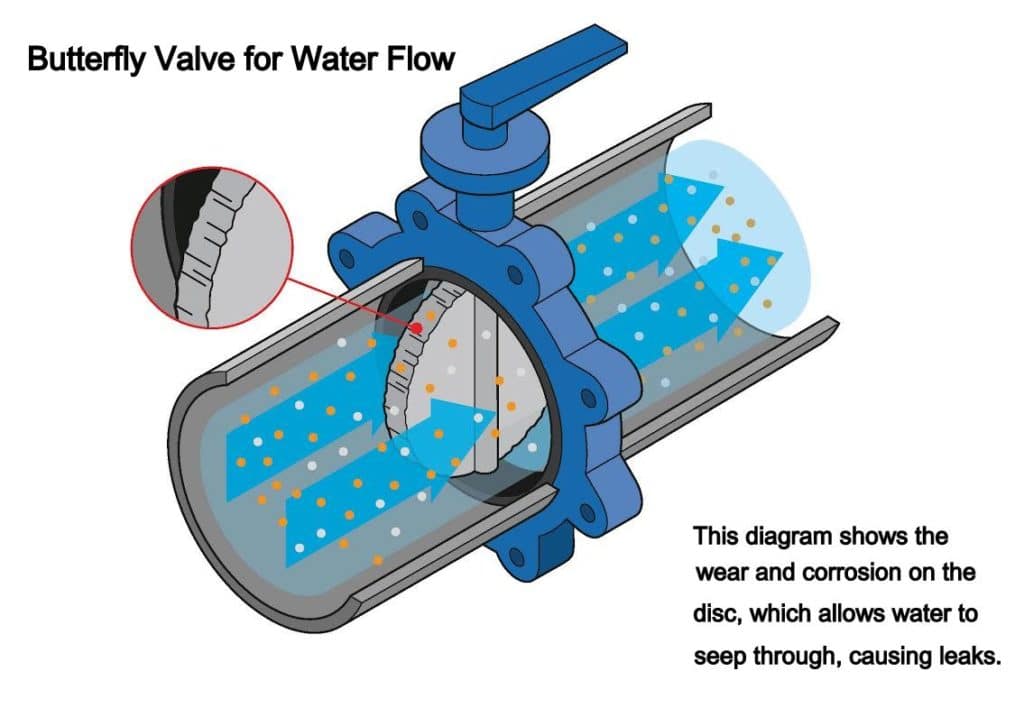

Generally easy to use but do cause more problems than others such as pipe blockages and a buildup of any solid media within the water flow which causes corrosion of the ball or disc. They are usually in a lever form or a round handle, which can be turned at a 90-degree angle. Instead of a washer like other types, these types of valves use a mechanical ball or disc to shut down the water supply.

The disc or ball on Butterfly & Ball Valves easily wear away and become corroded.

- Gate Valves

These valves have an inner mechanism like a gate, which moves to shut down the water supply. They are more expensive and cannot shut off water 100% as it can leak through the gate.

Knife Gate shutoff valves do not fully close off water, which causes leaks.

- Pinch Valves

These valves can be used in the most rigorous and rough commercial use. For example, for a safe transference of rainwater or in an event of flood, these valves will hold off the excess water without stretching or extending. They usually have a long rubber sleeve life and are manufactured to provide efficient engineering solutions for fluid and bulk solids transference.

A Pinch Valve has a flexible rubber elastomer sleeve which shuts off waste water applications with ease.

Waste Water Shut Off Valve Benefits with Pinch Valves

A Pinch Valve used as a waste water shut off valves main advantage is it’s free passage. Waste water shut off valves with a rubber closing sleeve have a true bore, meaning the passage is open fully at the exact diameter size of the valve. This type of waste water shut-off valve also has a clear bore which means there are no blockages during production, and there is nothing to restrict the flow. Unlike conventional valve types such as gate valves, ball valves or a diaphragm valve, the opening of a waste water shut-off rubber pinch valve is 100%, allowing a complete free flow of product and no clogging.

When Waste Water Shut Off Valves Can Be Useful

All of these waste water shut off valves types can be beneficial at a commercial or industrial scale for companies that want to shut down water supply in their facilities. However, if precision is what the user is looking for, they should invest in quality valves such as the pinch or squeeze valve. The pinch valve type waste water shut off valve is easier to take out of line and replace, should any leakages or failures occur.