Rubber Lined Valves Explained

A Rubber Lined Valve is a full bore or fully ported type of control valve which presents no obstruction to flow passage. There are a few types of Pinch Rubber Lined Valve based upon application.

Rubber Lined Valves are made up of 3 different parts:

– Body

– Ends (flanges, tri-clamp, threaded sockets, threaded spigot, weld-on ends)

– Elastomer Sleeve/Liner/Insert

- AKO Screwed Pinch Valves

Air pressure is used to close screwed rubber lined valves. They have screwed end connections with internal BSP thread, and are available in sizes 10mm to 125mm.

- AKO Flanged Pinch Valves

Air pressure is used to close flanged rubber lined Valves. They have flanged end connections, and sizes range from 25mm to 300mm. AKO flanges conform to BS4504 (New British Standard) NP (Nominal Pressure) 16. We do not conform to BS10 (Old British Standard).

Rubber lined valves are available either operated by hand (manual) or by air (pneumatic).

Industries using Rubber Lined Valves include:

– Food & Breweries

– Pharmaceutical

– Water

– Foundry (Sand, Cement, Solids etc)

– Tankers

– Chemicals

– Silos

– Sewage

– Agricultural

…plus many more!

Some materials are more abrasive than others and have different requirements. This will effect the type of sleeve, body, and possibly the type of ends needed for a particular job or application.

Softer sleeve materials are more efficient for the more abrasive products. Our standard Natural Rubber sleeves are popular because they are ideal for handling many abrasive products up to 80 degrees C.

Types of Sleeves available for Rubber Lined Valves:

– Natural Rubber: General use.

– Natural Rubber Food Quality: FDA Approved for the Food industry.

– High Temperature Natural Rubber: When operating levels are between 80-90 degrees C.

– EPDM: Suitable for products up to 120 degrees C, also available in food quality versions white/black.

– Viton

– Nitrile: Also available in food quality versions white/black.

– Silicon

– Hypalon

– Butyle

Pinch Valve body materials include Aluminium, POM (Polyoxymethalene), PVC, or Stainless Steel which is likely to be used in the food industry or in a corrosive environment.

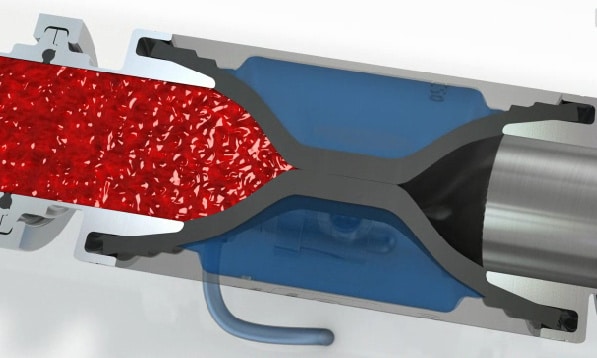

How does a Rubber Lined Valve work?

The controlling medium of air pressure or water is used between the valve body and the sleeve to give 100% closure (even against large abrasive particles) of the rubber lined valve. Exhausting this pressure causes the valve to immediately open. When open the sleeve allows full, unobstructed flow. The valve is operated via a solenoid/control valve and therefore does not need an expensive actuator.