Air Flow Valves – What are they?

Air flow valves are a popular type of valve used for measuring the flow of air or fluid in single or both directions. These valves are commonly used in pneumatic circuits to control the exhaust or rate of activation of cylinders and other pneumatic devices.

One of the most widely used types of air flow valves is an air operated pinch valve. These valves are known for being highly reliable and cost effective when it comes to controlling the flow of solids, fluids, and slurries. Pinch air flow valves are the best choice for applications involving abrasive and other challenging materials. These valves are used in a wide range of industrial and manufacturing applications. Some typical industries where this type of valve is used include beverage, food, waste water, cement industry, glass/ceramic/plastic, chemical, and bulk and solid handling industries.

More detailed examples (to name a few) of application areas for air flow valves include:

- Alumina powder

- Distillers feed

- Paper slurry

- Colourants

- Epoxy paint powder

- Broken glass

- Carbon ash

- Fiberglass granules

- Sodium Fluoride

- Talc

- Limestone

- Minerals

- Dehydrated lime

- Compounds

- Plastic pellets

- PVC resin

- Seasonings

- Cereal dust

- Sludge

- Coal

- Bentonite

- Wheat flour

- Zinc oxide

Air Flow Valves – How they work

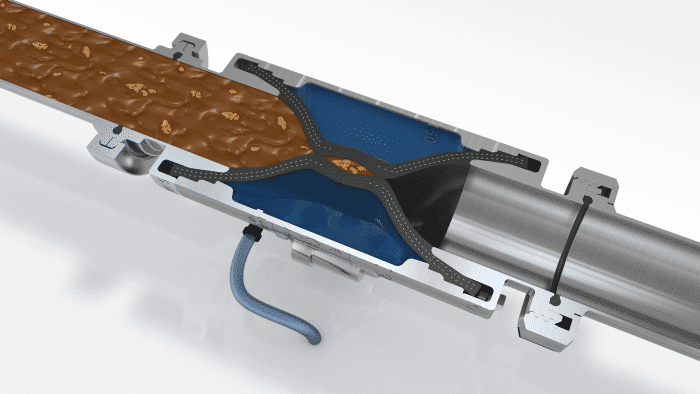

Air-operated pinch valves generally comprise of a type of housing, a specially reinforced, elasticized rubber hose (sleeve), and two socket end flanges or covers. The rubber hoses are usually centered and press-fitted with the help of a socket end flange or cover into the housing. They only require a minimum air pressure difference of 2 bar into the valve body, and do not require any additional actuators.

When compressed air enters the casing of the air flow valve, it compresses the sleeve having high rebound elasticity. The valves casing is designed in a way to ensure that its sleeve closes freely and forms a lip-like shape. When this happens, the air flow is tightly sealed off. The maximum operating pressure for air flow valves is around 6 bar, but it is dependent on the nominal diameter.

When the air supply is interrupted and the casing is drained or vented, the sleeve is opened due to the impact resilience. This enables the air pressure to flow through the entire passage of the air flow valve.

Air Flow Valves are a better choice

So you must be wondering why you should prefer air operated pinch valves over traditional plug, butterfly, and ball valves. The answer lies in the practical solution that air operated pinch valves offer for controlling

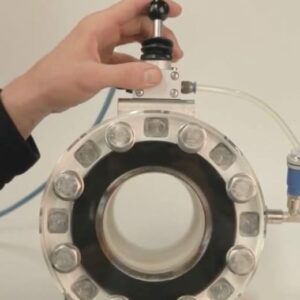

Butterfly Valves can clog easily where media gets stuck around the swivel disc.

abrasive granules, slurries, and powders, and viscous and corrosive fluids in pipelines. They are considered as the most viable solution for flow control and on/off applications.

Pinch-type air flow valves require low maintenance and are cost effective. They are ideally suited for a wide range of applications where they easily outperform other conventional options. This type of air flow valve features free passage of solids, full bore straight through flow, complete shut-off, and negligible head loss. These advantages make this type of valve a suitable option even when there are suspended solids present in the product stream.

On the other hand, butterfly valves for example do not perform as well as the pinch type air flow valves. As you can see from the image to the right, this butterfly valve has had a build up of media clog up the disc. This prevents the full flow stream, and effectively interrupts product trying to pass through. In turn, this creates even more of a build up, and in a short amount of time the butterfly valve will no longer shut off fully. This results in media seeping through the disc.

Air Flow Valves Benefits

Since air operated pinch valves have an elliptical and flattened casing design, they consume a minimum amount of compressed air, which ensures energy savings. Other major benefits include:

- Minimal frictional resistance

- Compact and low net weight

- 100% leak free and no blockages

- Straight through design with high capacity

- Easy replacement of the sleeve

- Positive shutoff and good regulating capability

To conclude, pinch type air flow valves are the more economical and reliable valve solution for most applications, including aggressive and viscous media.