The Soft Seated Valve Design

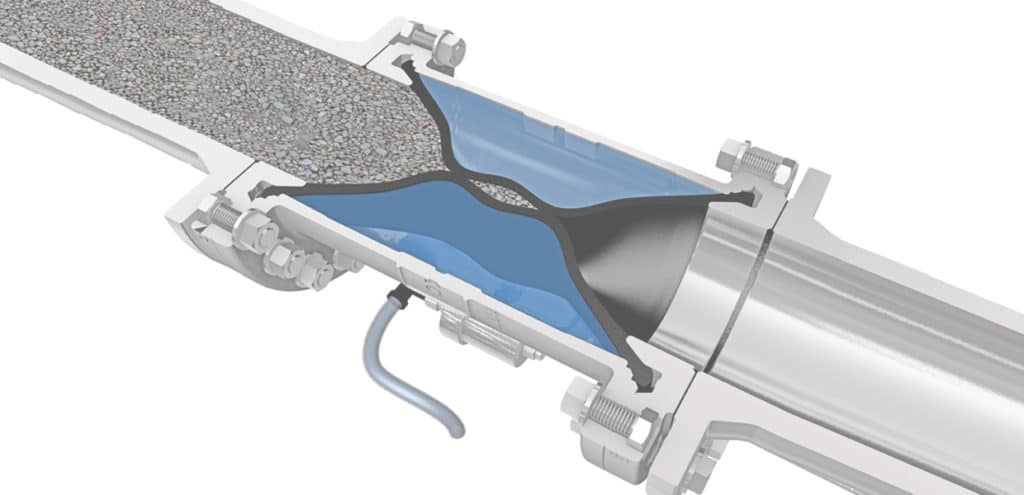

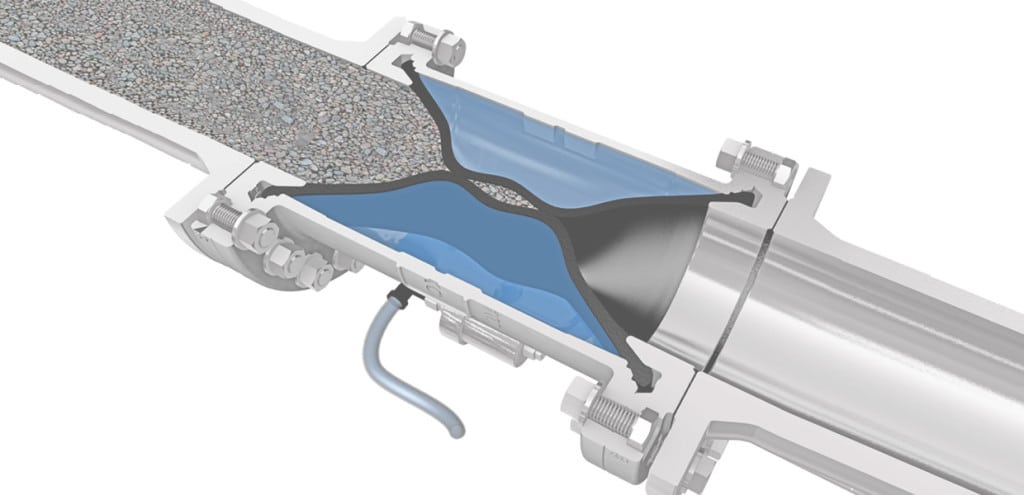

The soft seated valve design is to operate by supplying compressed air into the casing of the valve, which compresses the rubber tube to give a 100% tight seal. The body’s design guarantees that the valve tube can close freely to form a lip shape. This ensures that the product flow is completely sealed off tight and that the tube is guaranteed the longest service life at the same time. This closes the pneumatic valve and completely seals off the flow of the product.

As soon as the supply of compressed air is interrupted and the soft seated valve design casing is vented or drained, the specially manufactured tube is opened by its rebound resilience, enabling the pressure in the medium to flow through the full passage of the soft seated valve design.

A Soft Seated Valve Design is SIMPLE

The body or shell is the main pressure boundary of the soft seated valve design, which serves as the assembly or a framework that holds everything together. This housing also loads from the inlet and outlet piping. The pipe connections fitted either end of the body are either welded, threaded or bolted together. The throttling orifice or the rubber seat opening has a partition across the valve body.

Body of a Soft Seated Valve

Rubber Sleeve for a Soft Seated Valve design

An example of an end connection for a Soft Seated Valve design – Weld-on end.

Why a Soft Seated Valve is better than other valves

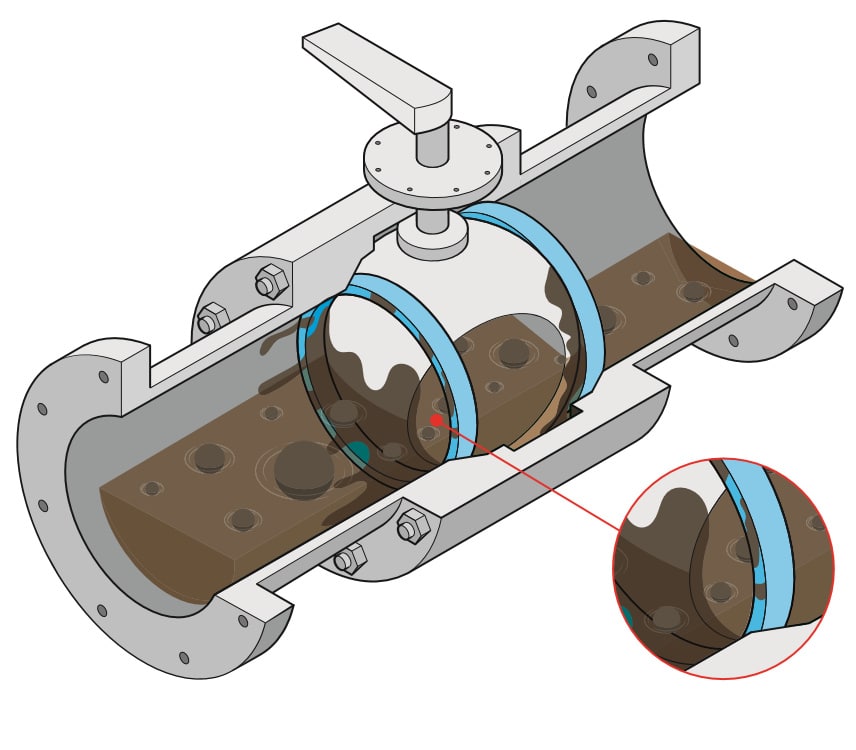

Many reliable soft-seated valve designs require air to open and close the valve and their operation is characterised as quick action. Other types of valves operate with geared mechanisms, metal balls, discs or gates. These types of mechanism are not as widely recommended due to many blockages being caused from the media becoming clogged around the opening.

This Ball Valve conveying dirty water & sludge cannot pass the product 100% due to dead spots from a build up of product on the ball.

Soft-seated ball valves are best used in the oil and gas industries. The flow of a ball valve is controlled by a rotational motion valve, which utilizes a ball-shaped structure to stop the fluid or allow it to flow freely. When the handle is turned to open this valve, the ball changes its position and rotates to the position of allowing the hole in the ball to align with the valve body outlet and inlet. When the handle of a ball valve is closed, the ball rotates so that it is in a perpendicular position to the flow of media. This should stop the flow of the product but after time, it does not immediately close effectively like it should. This is because of dead spots being formed from a build-up of media becoming stuck.

On the other hand, the soft-seated valve design requires no lubrication and can be easily used for any throttling service. The valve bonnet or rubber sleeve is the opening in the valve body and is the second dominant pressure boundary for the valve. With its extremely quick closing time and non-clogging rubber sleeves, a longer service life is achieved and the soft seated valve design is a lot more reliable. This in turn makes soft seated valves a very honest and positive valve solution.