Soft Seated Valve Performance

A soft seated valve is available in different types including operation by air, manually or as a control facility. Today, there are still some industries in which this variety of valve is relatively new technically, when compared for example with ball valves.

Although valves like the ball valve perform reasonably in certain applications, the situation is changing for many users. Various industries irrespective of size are now seeking and adding alternative technology to their present systems, such as the soft seated valve.

Soft Seated Valve Materials

When soft seated valves are compared to other varieties of valves, the construction of them is uncomplicated and designed for minimum maintenance with maximum performance.

The soft seated valve material is made up of three basic parts; the casing, a type of end connection and an inner sleeve or elastomer.

For the flanged type of valve, closure is by the application of air pressure, with the flanged connections varying in sizes between 40mm and 300mm.

Soft seated valves come in a wide range of end connections. The screw type valves in plastic are available in sizes between 10mm and 50mm. Whereas the screw type valves in stainless steel or aluminium are available in sizes 10-100mm. However, both flanged and screwed types of connections are obtainable for either manual or pneumatically operated valves of this variety.

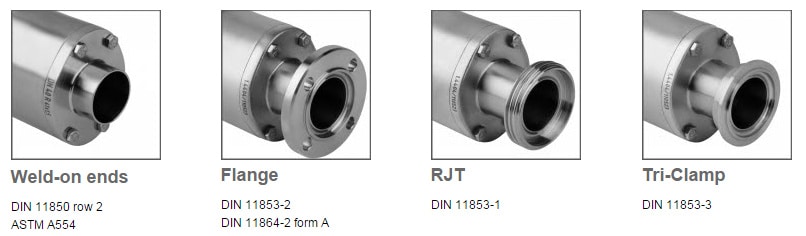

Soft Seated Valve End Connections

Soft seated valves are available with the following different end connections;

- RJT / Threaded Spigot – commonly used for milking applications

- Tri-Clamp – with a quick release coupling

- Flanged – either PN10/16 or ANSI 150

- BSP Threaded – screw in female socket ends

- Weld-on ends – attach different connections to either end

How the AKO Soft Seated Valve works:

Soft Seated Valve Types of Operation

A soft seated valve is available for use as the following;

-

Pressure Relief Valve

– For relieving a buildup of line pressure to protect a progressive cavity pump. A pressure relief type valve is a protective valve sitting in line holding back the flow of product – If for any reason there is a blockage in the line and the pump is pumping too high, the valve will open to relieve the line pressure and stops the pump from over-pressurising. Once the blockage is clear, the line pressure reduces, the soft seated pressure relief valve will close, and the pump carries on pumping at its set pressure.

-

Hand Operated or Manual Valve

– Mainly used on remote sites where air is not available, or in particular parts of a plant where it is impossible to get an air supply to. Alternatively, a user may wish to manually operate a soft seated valve by hand in general, rather than rely on an electrical or pneumatic supply. The benefit of a manual soft seated valve is that they can be left in the open or closed position and can therefore be fail closed in the same required position. Also, food grade sleeves are available for manual valves.

-

Normally Closed Valve

– Used when it is critical to have a fail safe system in place. For example under the bottom of a silo or hopper where the valve has to stay closed all of the time, because if the normally open valve is used and a loss of air or electric occurs, the valve would fail open, resulting in a spillage and loss of product. A normally closed soft seated valve will be closed all of the time to prevent this from happening.

-

High Performance Valve

– Mainly used if a user requires a valve rated above 6 BAR. 40 BAR rated valves are available with high performance valves. These soft seated valve types are also required in instances where a user may require a valve that is completely electrically or hydraulically actuated, or if a nominal bore is required in excess of 300mm.