Bulk Valves Reliability

Bulk valves with a pinching rubber sleeve close tightly, whatever the product you are conveying. They are the ideal solution for handling bulk solids and liquids, and even the most abrasive media without wearing the rubber sleeve/hose. These pinch bulk valves are proving to perform better than conventional valve types such as ball valves and butterfly valves where the disc or seals can become clogged or damaged.

Bulk valves will also close 100%, ensuring no leaks, even with liquids such as water.

Bulk valves pneumatic conveying systems are like a balloon – when air is pumped into a vessel with a product inside, the product will stay there but will have a lot of pressure built up. When the free flow valve is opened, the air pressure is released which pushes the product i.e. sand, water, concrete, chemicals or pigments along the pipe work to another location. This free flow valve system is a controlled way of transporting bulk media.

Bulk Valves Control Methods

Pinch bulk valves are designed to not only be operated by air, but can also be operated with water too. These valves close in exactly the same way when water is used and the same pressures apply. The bulk valve can also be controlled with a hand wheel. The hand wheel stem is attached to the rubber hose in the casing of the valve. Upon turning the hand wheel clockwise then the valve will close, and turning the hand wheel anti clockwise will open it.

The hand operated bulk valves with a rubber sleeve that pinches tight to close the media flow have a 100% true and full bore, and also seal off 100% to ensure no product leakages. Unlike older conventional valve types such as ball valves or check valves where the media can become either clogged around the ball or disc, or begin to seep through and leak.

Bulk Valves Maintainance

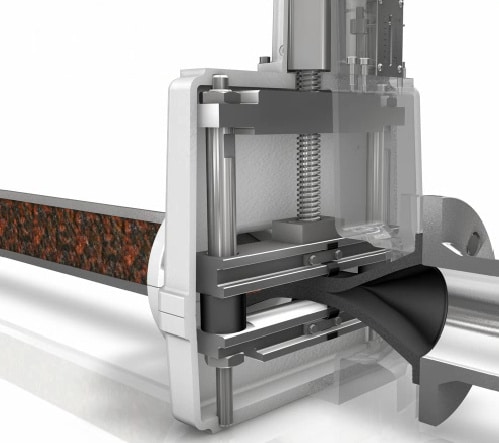

The maintenance of a bulk valve is simple, with the rubber sleeve or tube inside the body of the valve casing being the only wearable part. This sleeve will need replacing after some time, which all depends on the details of the application. The sleeves are replaced with a simple fitting tool as pictured.

The amount of pressure being used to close the bulk valves will have an effect on the lifetime of the valve. AKO have various different case studies from existing customers that may offer some indication, but it is always best to contact the AKO sales team to discuss your application first.

Bulk Valves Assembly Videos

With the help of detailed assembly instructions and assembly videos, pinch bulk valves by AKO can be easily replaced by a user on site. These videos can be downloaded from AKO’s website – The UK’s leading bulk valves/pinch valves manufacturer.