Wear Resistant Valves in Endless Industries

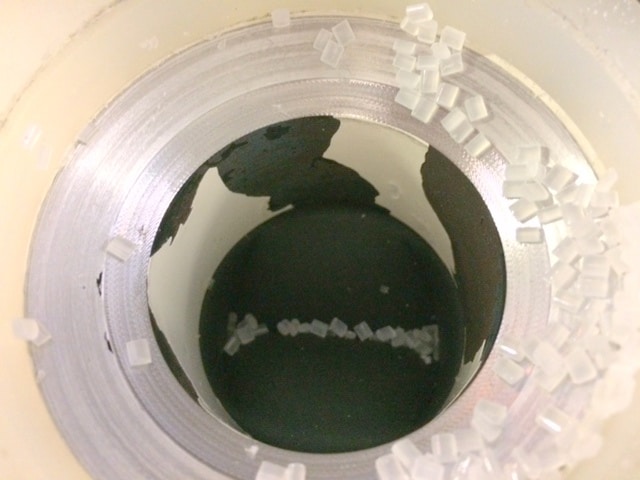

Wear resistant valves comprise of a rubber pinching tube inside the valve body that helps in controlling the flow of media. They have a robust construction and are very economical, which is why they are used in a wide range of industrial applications. The rubber sleeve is made up of high quality natural rubber and is the only part that needs to be replaced. Moreover, these wear resistant valve types require little to no maintenance and can be retrofitted in almost any application.

Wear Resistant Valve Applications

Due to their cutting edge features and many benefits, wear resistant valves with a rubber hose that squeezes closed are used in some of the major industries, including:

Pharmaceutical

Pharmaceutical companies manufacturing different types of small-sized medicines mostly opt for wear resistant valves. As they have to uphold high quality standards, they use wear resistant valves having tri-clamp end connections made of stainless steel, which are corrosion and acid-resistant. Mostly, a closed version of wear resistant valves is used which opens upon application of air to pass tablets falling due to gravity.

Cement Industry

Wear resistant valves are widely used in the cement industry. This is because of the high quality natural rubber sleeves that are embedded in the valve body that allows strict control over flow of cement and concrete media. Moreover, when they are coupled with some valve accessories, such as aerators or aeration pads, they streamline the flow and eliminate the possibility of material sticking to the bin wall.

Applications Requiring Controlling Water Flow

Water pumping systems require equipment that can help operators to control the flow of water. Typically, wear resistant valves have a smaller bore size, which ensures that it is tightly sealed and there is no leakage. The wear resistant valves are extensively used to support landfill site operations where air pumps are functioning at a pressure of 4.5 bar and pumping media to another area. The wear resistant valve closes whenever the tank fills up to avoid over pumping.

Another application is in recycled water systems where wear resistant shut off valves are used. In these systems, contaminated water is filtered and sent to a suction pickup system. With a wear resistant valve installed in a recycle water system, operators can easily control the flow of recycled water, making the job manageable and easy.