Valves for Slurry Advantages

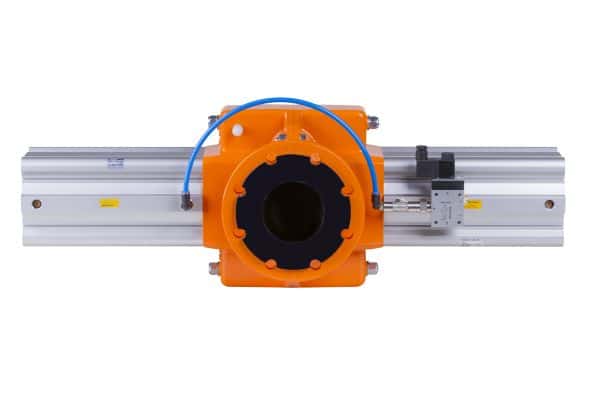

One of the main reasons why pinch valves are the optimum choice for controlling the flow of slurries across a wide industrial area is because they are embedded with a flexible tube that produces a 100% tight seal when it is pinched/shut off. When purchased from a reputed pinch valve manufacturer such as AKO, valves for slurry offer high quality, are up to industry standards, offer easy control over media flow, and the full bore design limits leakage to almost zero. Valves for slurry by AKO have excellent resistance to corrosion and abrasion, which is another reason why industry experts prefer them in such applications.

Why Valves for Slurry (Pinch Valves) are Preferred

Valves for slurry with a pinch-closed rubber sleeve have a long service/working life, require little to no maintenance, and are extremely reliable. They also have high tolerance against particulates present in most types of slurries and have zero deal volume. When the valve is fully open, the media flows through it just like it would in a rubber lined pipe, and in the closed state, it provides complete isolation, rendering complete control over the flow system. Valves for slurry by AKO have a straight through design with no cavities or pockets acting as material collection points that decrease the operational efficiency.

Read more with some of AKO’s real life case studies below, involving AKO Pinch Valves in aggressive slurry/liquid applications:

Valve with methalene chloride & epoxy resin

Valves for acidic water making steel rods & wire

Valves for Slurry – More Highlights

The valves for slurry by AKO are not subject to scaling, and turbulence is nonexistent, ensuring its longevity and consistent performance. Inside the valve body, a highly reinforced rubber sleeve is placed, which is the only part that comes in contact with the slurry. This rubber sleeve also flexes, which creates a self-cleaning effect. The high quality rubber used allows the valve for slurry to be used in applications where surges or high pressure is involved.

Pinch valves can also handle abrasive slurries and fluids. Some examples are pulps, sugar pulp, sewage, lime slurry service, food and beverage industry, chemicals, medicines, and chemicals.

See more pinch valve industry examples.