Wear Free Valve – What is it?

A wear free valve of the rubber pinching type ensures safe and precise media control and flow operation in a diverse range of industrial applications. They are specially designed to sustain the damage caused by highly abrasive and corrosive materials. This type of wear free valves are made using cutting-edge technology to construct highly durable and corrosion-resistant components, allowing the valve to be operated in different ways according to the requirements of different applications. Due to this, these wear free valves provide an accurate measure of flow performance with easy and smooth handling of the process. Moreover, they ensure that there is no leakage in the system, along with a long-life operation.

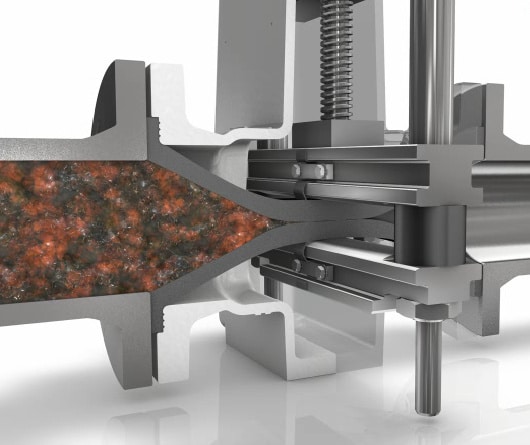

How A Wear Free Valve Works

This type of wear free valve is usually operated with the application of air pressure. They are available in two different types, normally open and normally closed valves. In the open version where no air is present, the initial position of the valve is open and the flowing media passes through it freely. When air is introduced into the system, the walls of the rubber sleeve are squeezed together, cutting off the flow path and shutting off the valve. The most common material used in the wear-free valves are natural rubber, which can be operated at 2.5 Bar for closing the flow path. (See more about operating pressures). Natural rubber works well against abrasive, corrosive, and fibrous materials.

In the closed version, the original position of the valve is closed, which is achieved by one or two pistons pinching the rubber sleeve. When the air is introduced, the flow path opens and the rubber sleeve inside the body opens because of the function of pistons. The wear free valve comes back to the initial position when the air pressure is taken off. Moreover, these valves are very easy to maintain and offer a cost-effective solution.