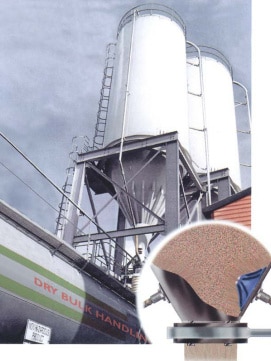

Aerators are Key for Free Flowing Hoppers & Bins

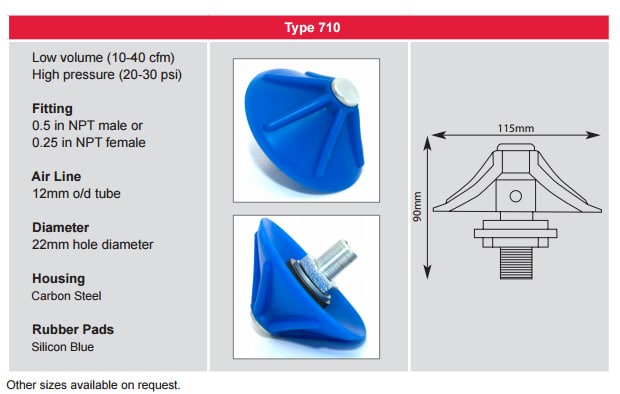

Aerators (also known as aerator pads, airbrators, and vibrating cones) are a simple component made up of a rubber cone or ‘mushroom’ shaped body, with a threaded screw connection, washer and fixing nut. These small but important devices are used for aeration, to simply get dry powders, granules and pellets to move.

Available in blue for general purpose, or white for food products, aerator pads are being used more and more for free flowing bins.

Aerators – How They Work

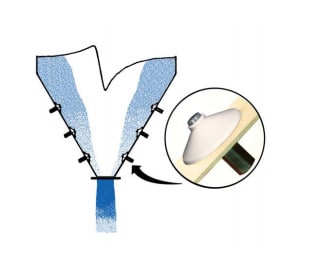

A hole is drilled on the outside of a hopper, silo or bin, for the aerators to be placed through the hole on the inside of the hopper, and a nut fixes them into place on the external wall. Once fitted, a piece of plastic pipe with a push fitting connection is connected to the aerators. Compressed air is supplied through this pipe which causes the aerator to vibrate. The aerator pads can vibrate constantly for required periods of time, or air can be pulsed into them.

Causing the aerators to vibrate is the key element to how they work. The vibration from the rubber pad ensures that any product passing through the silo, hopper or bin will pass freely without bridging, caking or building up and clogging.

Sometimes, aerator pads are fitted to remove clogged dry products from the internal hopper walls, as well as preventing the product from further clogging. Effectively, they keep bulk dry materials moving.

Aerators Application Examples

Aerator pads can be used for a very large range of different dry media for flow aid – almost every dry product that flows through a silo, bin or hopper. Some examples are listed below:

- Corn

- Flour

- Pellets

- Seed

- Sand

- Sugar

- Animal Feed

- Polymer

- Cement Powder

- Cattle Cake

- Fodder

- Powders

- Granules

AKO UK stock both general purpose and food quality aerators. Contact us today for a quotation.

For further product specification and more information, please see aerator pads.