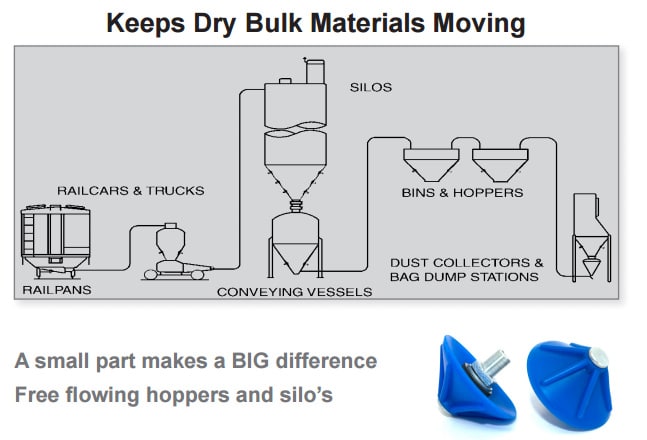

Fluidisers For Free Flowing Vessels

Air fluidisers are small and simple cone shaped components that solve bulk dry powder and granular material flow problems, acting as a flow aid. Bridging, caking, compacting and rat-holing are common reoccurring problems in large vessels including silos, hoppers and bins. A simple solution for solving this issue is to install air fluidisers around the vessel, which give off a gentle vibration using low volume directional airflow and aeration. This vibration and aeration clears away any trapped or clogged media from around the internal walls of the vessel, creating a free flowing hopper.

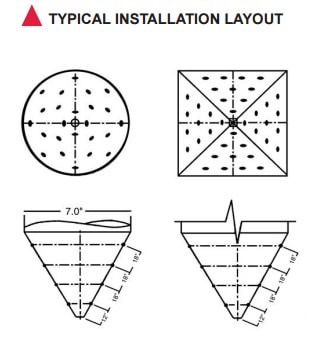

Silo fluidisers are extremely cost effective, and research has shown that only a limited number of the fluidiser units often need to be installed for instant, faster powder discharge flow. A typical installation layout of the aerator pads is shown below.

Fluidisers: Features

Even the most difficult of products can be released from a vessel wall using air fluidiser pads. They are very easy to mount, allowing safer installation and access from outside of the silo. Other features include:

- FDA white food grade pads, as well as general purpose blue pads

- Eliminates back flow & airline clogging

- Aeration action

- Minimal air consumption

- Unique design

- Directional air flow

- Minimal maintenance required

Fluidisers Applications

Below is an example of a hopper where the aeration pads are installed. Inside this hopper, air is forced between the chamber wall and the dry media, creating a cascading effect. Aeration loosens up the product allowing it to flow, and the gentle vibration from the pads prevents further compaction or plugging.

Some types of applications where fluidisers (also known as aerators or airbrators) are ideal for keeping a good flow of product are:

- corn & grain

- animal feed

- flour

- sand

- ceramic powders

- sugar

- dust

- ash

- pellets & granules

- cement powder

- fodder

- other powders