After watching a demonstration video of AKO’s VMCE type Pinch Valves, a company manufacturing soft cheese were keen to use them to replace existing butterfly valves on site.

They were particularly impressed by the fact that the Pinch Valve is hygienic and CIP (clean in place) capable. AKO offered a food quality EPDM internal rubber sleeve which is rated to 120’C, so the company’s CIP cleaning process at 85-90 degrees Celsius was not a problem. The CIP process within this soft cheese manufacturing process is typically carried out once a day, washing the lines containing the pinch valves with a caustic solution and uses 1-2% vol peracetic acid sterilant solution on the final rinse.

There is no likelihood of product or bacteria build up in any areas of the pinch valve, since it is self-cleaning, and the sleeve offers a 100% straight through bore with no dead spots.

Only One Wearable Part with the Pinch Valve

The rubber element inside the pinch valve is the only wearable part, and will need replacing from time to time, but the exact lifespan of the sleeve cannot be guaranteed or fully advised. The sleeve lifetime all depends on each individual application – including the media, temperature, the line pressure and how often the valve will open/close. What AKO can confirm, is that our Pinch Valves have been tested closing at 6 BAR against zero line pressure and with no media up to one million cycles. AKO would recommend keeping a spare sleeve on the shelf in case of emergency failures or a scheduled maintenance program.

Pinch Valve Performance

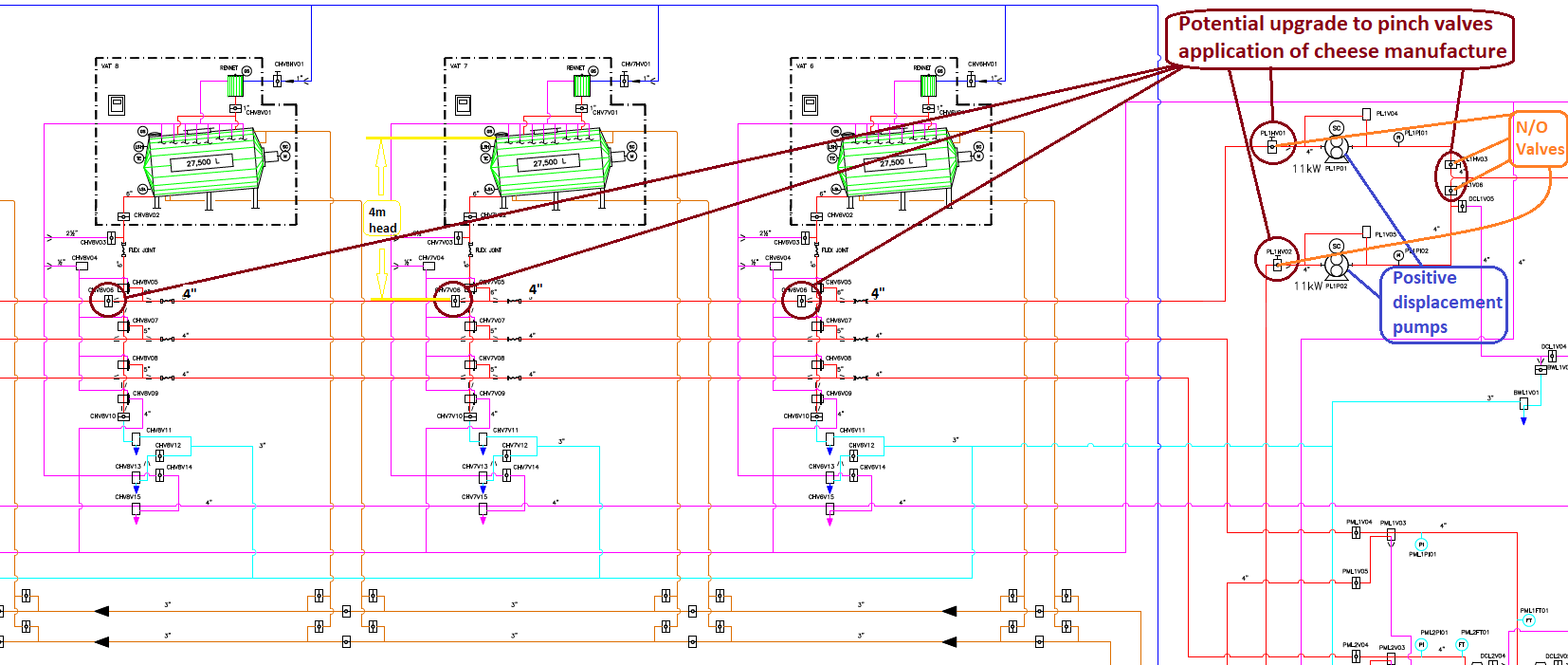

As the product flow of soft cheese into the base line only sees a 4m head pressure to the base feed line to the pump, 4m head equates to 6PSI weight of product which the pinch valve holds back with approx. 0.5 BAR pressure. This decreases as the product is pumped out of the VAT. An air pressure regulator pre-solenoid was fitted, enabling pressure to be reduced to the minimum requirement, prolonging the lifespan of the rubber sleeve.

The below diagram shows the application and where the pinch valves were fitted.

The Pinch Valves are used to hold back the product leaving the vessel and to stop it flooding backwards down the line, whilst the tank before it is being emptied. The head is typically around 3.8-4.0m of cheese curds above the proposed position of the pinch valve.

The pinch valve only requires enough pressure to keep that head of product back. Once released, the product will flow towards the positive displacement pump. The system is usually turned around 4 times a day, so in essence each blocking pinch valve in the main line is only being used (energised) 4 times a day. The pinch valves are not used during CIP and those around the pump are only used in a breakdown situation.

Since using the AKO pinch valve within this application, they have proven to be a great solution and give the client more benefits and yield improvements, in comparison to the previously used butterfly valves which had a tendency to become clogged.