Find out why it is important to re-sleeve and maintain AKO Pinch Valves correctly, with maintenance videos showing the simple step by step process for each valve model.

Pinch Valve Maintenance, Failures & CAD

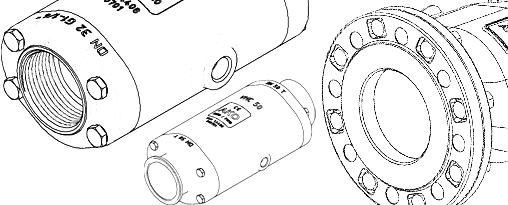

CAD data can be useful for designing new machines or systems and configuring a Pinch Valve into your drawing. AKO Pinch Valve CAD drawings are free to download!

Are you experiencing problems with a Pinch Valve, such as leaking, or damaged/ruptured/deformed rubber sleeves? At AKO, we find that these problems are rare but can happen due to lack of operating and maintaining the Pinch Valves correctly.

These minor problems are quick and simple to rectify with just one or two tweaks and by taking on board some knowledgeable advice to give your Pinch Valve it’s best possible service life.

The Simple Pinch Valve Principle

AKO Pinch Valves are made up of only 3 parts (body/housing, end connections & rubber sleeve/membrane), compared to other valve types such as Knife Gate Valves which have added extra rings, seals, packing etc. In effect, Pinch Valves have a much greater total cost of ownership, making the Pinch Valve more valuable.

The video below shows the simple function of the AKO Pinch Valve, with the rubber sleeve closing into a lip shape. The rubber sleeve/membrane closes in the same shape every time, and ensures a 100% tight shutoff.