Sanitary valves with a rubber pinching hose are specially designed for applications where sterility, purity, and cleanliness are of paramount importance. These valves are made to be sanitize-in-place (SIP) and clean-in-place (CIP) capable in order to prevent contamination by bacteria and any other foreign element. Common features of sanitary valves include a polished contact surface, free of crevices and dead spots, and easy cleaning. They are mostly used in chemical, medical, pharmaceutical, biotechnical, food, and dairy applications.

How Do Sanitary Valves Work?

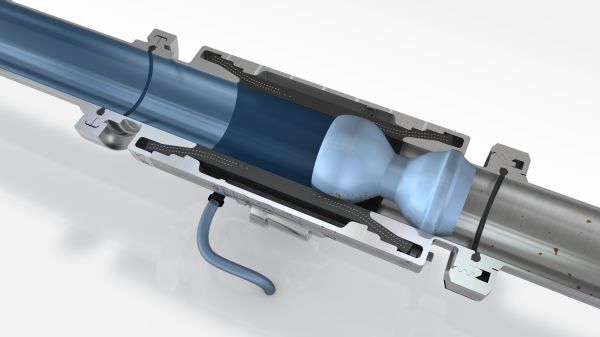

The sanitary pinch valves comprise of a robust body made of stainless steel that shuts off the flow of material by squeeze closing the passage through fluid pressure. They are full bore valves that enable proportional control of the flow or to be used in an on/off manner. Sanitary valves are designed for low pressure control, and low flow rate of fluids to maintain their sterility.

The advanced sanitary/aseptic pinch valves are fully automated, due to which poor control and inefficiencies of manually-operated valves have been eliminated and yield better and accurate results in high value applications. Sanitary valves consist of three major components: a rubber sleeve/hose/diaphragm, a shell body of pharmaceutical grade stainless steel, and sometimes a digital controller for maintaining valve reliability and enhancing its performance.

All the three components work in unison to maintain the high efficiency of the process. The digital controller allows the user to monitor the condition and operating health of the valve assembly, thus enabling them to know when the system requires maintenance.

What makes Sanitary Valves a Better Choice?

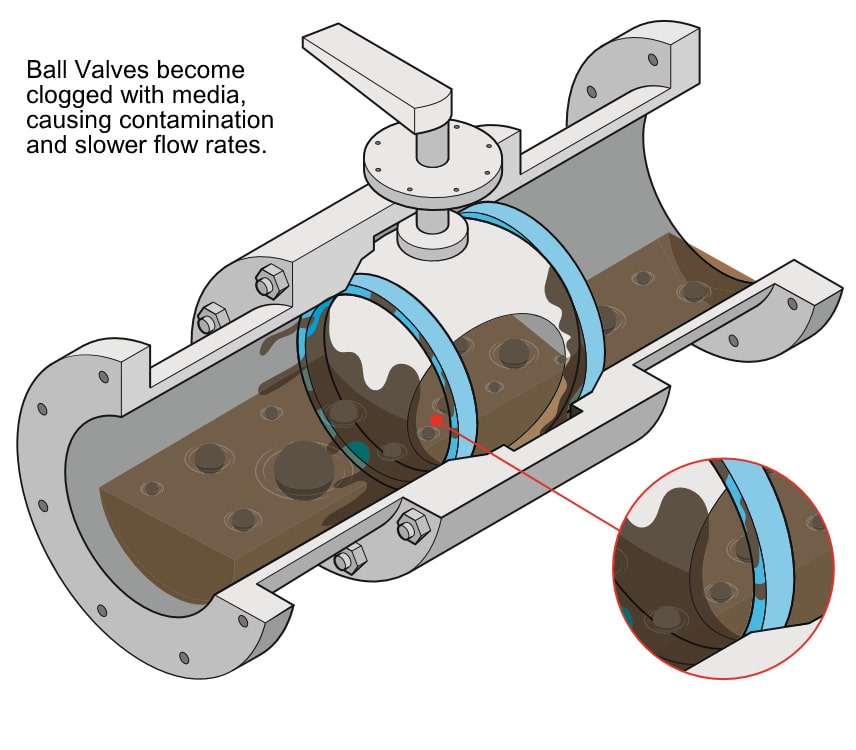

The sanitary pinch valves are constructed in a way to ensure accurate control of the process and high purity of the flow media without contamination. Unlike conventional valves such as ball valves, pinch/squeeze type valves have high positioning resolution which provides better control over flow rates. The valve construction allows the system to self-drain, preventing any kind of contaminant build up. Moreover, the stainless steel shell enables hassle-free changing of the process tubing.

Since these valves have a straight-through port design, they are free from any dead spots and crevices, reducing the possibility of bacteria growth. The only wetted part is the flexible sleeve, which is made of FDA approved, food grade rubber.

Ball Valve open but not allowing 100% media flow.

Benefits and Applications of Sanitary Valves

- Fail-close configuration

- High SIP and CIP capability

- Self-draining

- High corrosion resistance due to stainless steel components

- Disposable tubing ensures no physical contact with the flow media

- Lightweight and compact design

Due to their ability to be used in highly controlled and sterile environments, they are an ideal option for the following applications:

- Food, Diary, and Beverage – the manufacturing of products requires controlled processes and sterile equipment to ensure their color, texture, aroma, and taste is the same in every batch.

- Biotechnology, Medical and Pharmaceutical – since the process fluid will eventually be consumed or integrated in the human body, the sanitary valves make sure that it is contamination free.

For more information on high quality and reliable sanitary valves, please see the AKO VMCE type Pinch Valve.