Free Flow Valves for all Applications

Free flow valves (Pinch Valves) are a great choice for industrial applications that require precise flow control and shut-off of the flowing media. They are the most practical solution for proportional or on/off flow control of fibrous, corrosive, and abrasive products. These valves are also suitable for suspended solids, granules, and fibers, giving them an upper hand over conventional valves that mostly end up being plugged. They provide an unhindered flow of material due to their high flow coefficient (Cv).

How Do Free Flow Pinch Valves Work?

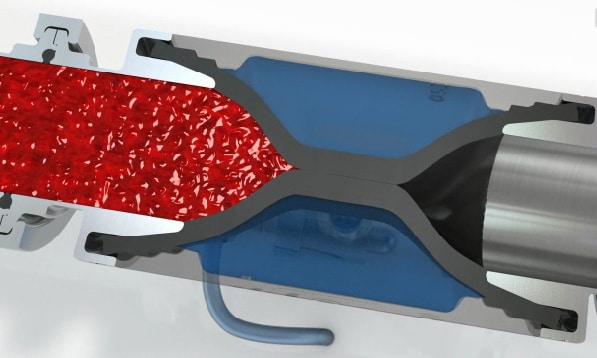

The free flow valves work through a positive displacement mechanism, which is similar to that of a peristaltic pump. The valve is activated through a manual or pneumatic actuator, when the elastic tubing element inside the valve housing is pinched closed. When the valve is reopened, it gives a completely unhindered flow path to the fluid (gas, liquid, or powder) passing through the passage of the valve housing.

The unobstructed flow is due to the straight-through bore which considerably reduces shear that may be present in the process line. The best part about free flow pinch valves is that the bore enables the valve to drain the fluid in any position, saving the user from the hassle of installing complex components.

Free flow valves have a 100% tight shutoff.

The free flow pinch valves comprise of a special, reinforced elastomer sleeve that ensures rapid response to the applied pressure of the fluid. This elastomer sleeve controls pressure ranging from fully open to bubble tight shutoff and fully closed.

What Makes Free Flow Valves A Better Choice?

Unlike ball and butterfly valves, the free flow design offers minimum frictional resistance, low operating and maintenance cost, and 100 percent free flow of media, ensuring no leakages, damages, or blockages. Moreover, these valves function directly through the pilot air signal, making them a cost-effective option over other types of valves.

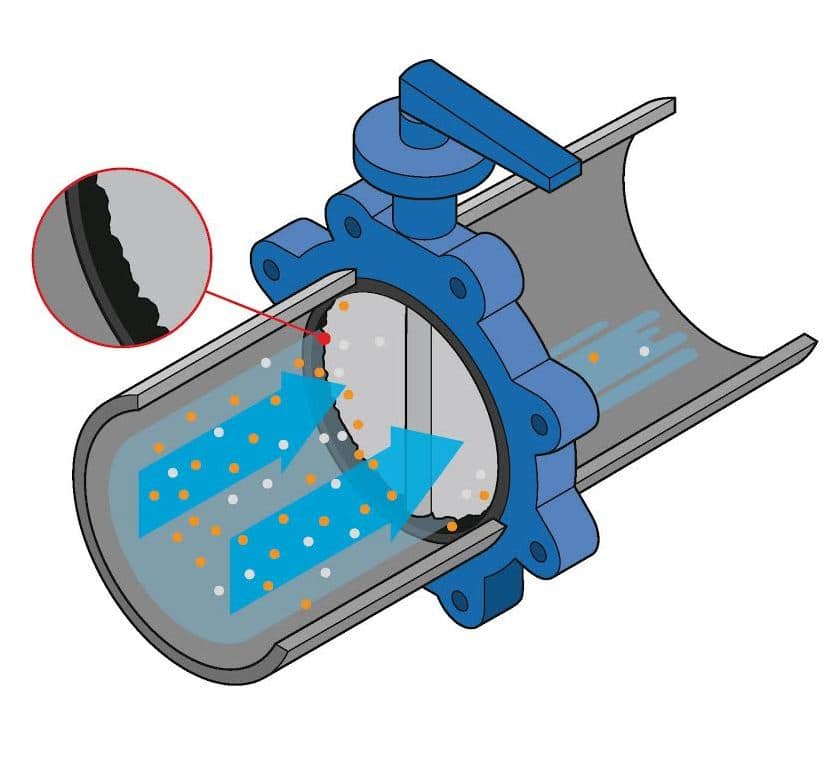

The corrosion of the seat material on Butterfly Valves make the seal not tight, allowing product to seep through – especially water and other liquids.

Another positive aspect of free flow valves is that the sleeve is the only moving component which is susceptible to wear, and can be replaced easily without any hassle. The sleeve is made from a special elastomer, which eliminates the need for seals or stem packing. This prevents them from wearing out and leakage. In addition to this, the sleeves tend to last longer because they are designed to close in the same manner every time.

Butterfly Valves can become quickly clogged with media, unlike free flow valves

Benefits and Applications of Free Flow Valves

The following are a few highlighting benefits of the free flow pinch valves:

- Self cleaning

- Easy maintenance

- Only one wear part, i.e. the sleeve

- No plugging/blockage

- No seals, bearings, or packing required

- Lightweight

- Free passage of solids in both directions

- Complete shut-off with suspended solids and liquids

- Negligible drop in pressure

The free flow valves are suitable for almost any industrial application where flowing products such as slurries, granules, pastes, powders, liquids, pigments and similar materials are metered, blown, flow by gravity, pushed, or pumped through pipelines. Some of their major applications include:

- Agriculture

- Power plants and coal slurries

- Food

- Cement, lime and aggregate plants

- Pharmaceuticals

- Sewage and Water treatment

- Water

- Chemical

- Powder painting systems

Our range of free flow pinch valves are made of high quality materials and are extremely durable.