Bladder air valves are important industrial products in a huge assortment of valve related industries and as user requirements become more demanding, so do customer expectations. The market dictates that there must be a specific bladder air valve able to serve in practically any application or operation in any industry, anywhere.

For example, a type of bladder air valve used in mining, chemical processing and the recycling of paper, is air operated with a cast iron or aluminum casing. In an operation processing solid materials, larger sized diameter air operated bladder air valves of the same variety would be used but with a steel casing.

The critical sleeve or elastomer would be pre-determined for compatibility with the processed products.

Bladder air valves manufacturers must be prepared to cater for different circumstances in valve operation such as a low pressure service situation.

In applications where “on – off” valve control facilities are needed, an air operated bladder valve with an aluminum casing and a flexible rubber sleeve would be required as a solution. Whereas industrial operations such as water, chemical and solids require bladder air valves with strong, flexible casings.

An alternative valve type is also air operated but with a stainless steel body and a rubber sleeve inside the bladder air valve. This is usually the given preference in a sanitary environment.

Bladder Air Valves with True Bore

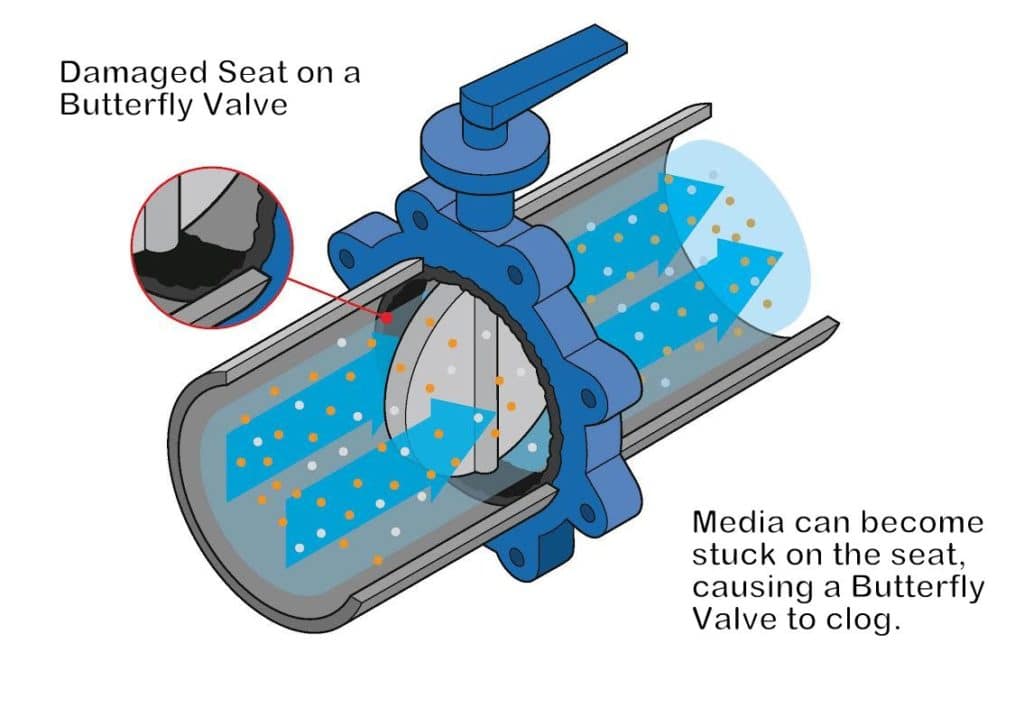

Bladder air valves are becoming an increasingly popular option over other conventional valve types such as ball valves, butterfly valves, globe valves and check valves. The soft seat of a bladder air valve makes the unit so much more versatile and durable, with no clogging.

Bladder air valves have an elliptical shaped body, which enables the rubber tube inside to close in the same way every time. This lengthens the life of the rubber tube.

A bladder air valve is a newer, modern type which has many fantastic advantages over the ball valve and butterfly valve etc, including:

Bladder Air Valve Advantages

Free flow of product

100% clear, open nominal bore

No restriction on product flow

A range of different rubber tubes to suit almost any application

Multi-functional modular system

Mix and match with a range of different end connections

Suitable for pharmaceutical applications

FDA Approved – food safe