Aeration Pads Enhance The Flow of Dry Solids

The aeration pads were originally launched in 2001 but due to the success, and to stay ahead of the competition the product has now been improved.

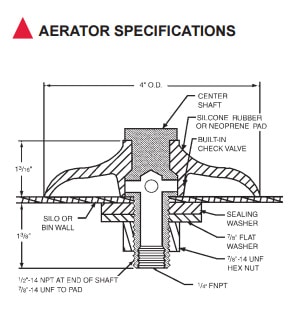

Instead of having different types of aaration pads in the range, there is now one specification for all applications. The housing and lock nut are stainless steel 316, and the pad is either white neoprene which is a fully FDA approved material, or blue silicon for general purpose.

Having only one specification allows AKO to carry more stock of the aeration pads, enabling the ease of supplying large quantities from ex stock, as well as keeping the prices low due to increased production.

Other improvements of the aeration pad include:

- lower profile

- a smooth pad surface to encourage product flow

- a higher temperature rating (300degf).

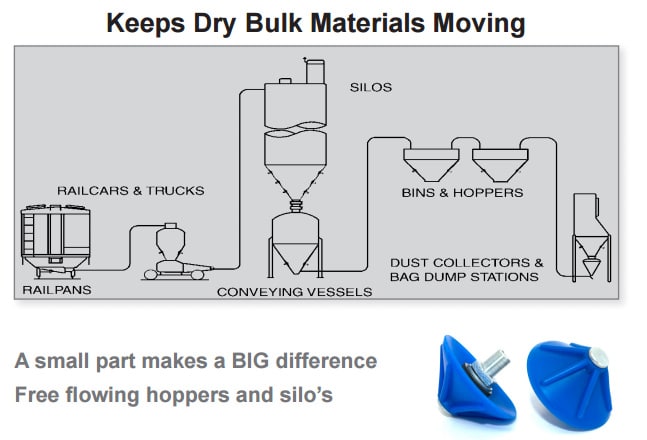

Aeration Pads Areas of Application

The wide range of applications where aeration pads can be used include; Alumina, Ash, Barlite, Bentonite, Cement, Carbon Black, Clay, Calcium Carbonate, Corn, Cement Clinker, Dust, Fly Ash, Fertilizer, Flour, Gypsum, Lime, Perlite, PVC Resin, Potash, Salt, Sand, Soda Ash, Sugar, Soup Powder, and many more.

Problem Solving with Aeration Pads

The AKO aeration pads have now solved a common problem for many companies. On a recent high profile job for a large cement manufacturer, the aeration pads have been fitted to silos.

The aeration pads are fitted inside the lower walls of the container. Pressurised air is applied to the outside of the pads, causing vibration and a deliberate leakage of air that is imparted to the bulk powder/granule product, which in turn leads to uninterrupted full flow of product through the discharge valve.

AKO UK’s vibrating aeration pads promote more product fluidisation than other rubber competitors. In addition, the system can operate from 5PSI to 60PSI, so is equally compatible with both high pressure/low volume blowers or low pressure/high volume compressors. The vibrator housings have greater open areas, giving increased airflow and higher levels of vibration to prevent the product from adhering to the container wall.

The simple system ensures no more blocking or rat holes. The AKO Aeration Pad will economically solve these and other common material flow problems, ensuring a plant keeps production to a maximum.