Tight Shut Off Valves Design & Function

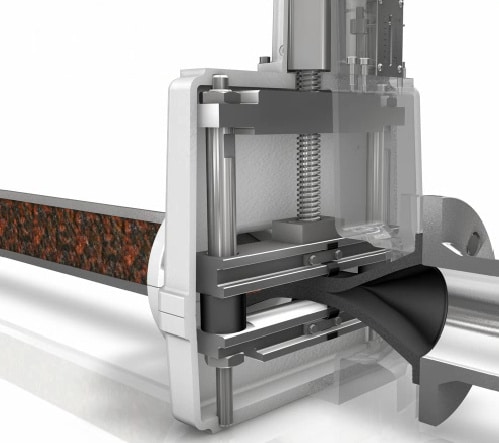

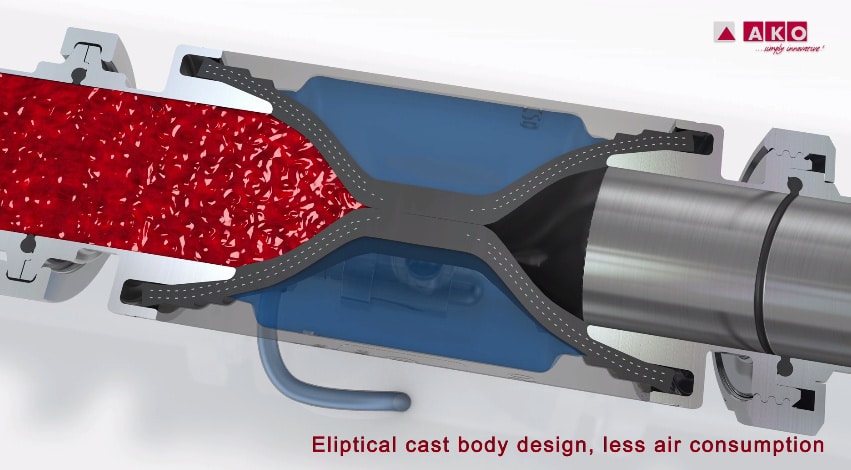

Tight shut off valves with a rubber hose that squeezes closed are designed to fully open and close tightly to ensure zero leakage. These valve types are relatively simpler in terms of design and operation compared to a ball valve for example, allowing for a repeatable and reliable tight shut off operation. These squeeze-closed types of tight shut off valves are used as a safety function in applications where immediate cut off of the flow of media is of paramount importance. Resilient seat trim, high actuation force, exacting seal geometry, and long-life seating material are some of the highlighting features of this tight shut off valve, ensuring repeatable tight shutoff performance with high integrity.

Tight Shut Off Valves – How are they the best choice?

It has been found that squeeze or pinch type shut off valves are the best, offering a quick and complete shutoff operation of a continuously flowing media. One of the main reasons why they are preferred over other types of valves are their rubber sleeve present inside the housing that closes down tightly so as to ensure the 100% closure. Moreover, the reaction time is extremely fast – less than one second – making these tight shut off valves a suitable choice for a wide range of applications.

Tight Shut off Valves Benefits

One of the benefits of using tight shut off pinch valves is that they do not become blocked, regardless of the type of flowing media. On the other hand, butterfly or ball type shutoff valves experience unnecessary buildup, which increases over time, hindering the flow and reducing the efficiency. That is why tight shutoff pinch valves are considered as an ideal solution for applications involving the flow of corrosive media, slurries, coarse substances, and powders.

Other benefits of this type of tight shutoff valve include:

- optimized closing times

- 100% shutoff with no leakages

- little to no maintenance requirements.

See more pinch valve advantages and disadvantages.