Abrasion Resistant Valves with a Rubber Squeezing Sleeve

More and more engineers and plant workers are opting for the Pinch Valve when fitting or replacing abrasion resistant valves. The Pinch Valve is a highly robust type of valve that is extremely reliable, with a very good elasticity. One of the main positive factors of this type of abrasion resistant valve is that it has lightening fast opening/closing times, ensuring a quick shutoff.

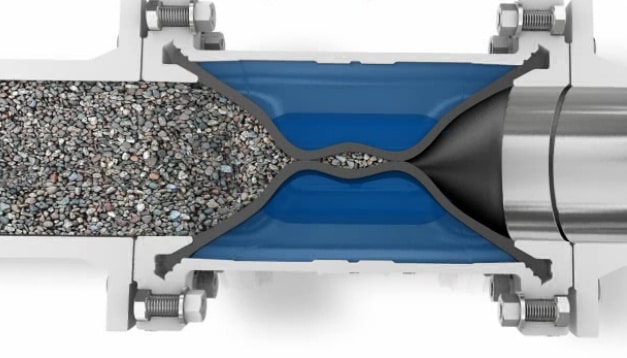

The rubber sleeve inside the body of these abrasion resistant valves is available in a number of different rubber qualities, many of them being good for abrasion with abrasive and corrosive media.

It is becoming more apparent that engineers have replaced old knife gate sliding valves, butterfly valves or ball valves with the Pinch Valve because they are proving to perform a lot better, and in return they last longer.

See more benefits of the Pinch Valve.

Cross section of a Pinch Valve with abrasive gravel.

Abrasion Resistant Valves Do Not Clog

Build up of media around the disc on a butterfly valve causes it to become blocked.

The rubber sleeve inside a Pinch Valve is self cleaning. When the sleeve opens and closes, the movement of the rubber folding in the same shape every time ensures that any product that has been left behind drops off. These abrasion resistant valves are also piggable, CIP capable and SIP capable.

There is nowhere inside the Pinch Valve for any media to clog the bore. Unlike other conventional style valves such as the butterfly valve, where media can easily build up around the swivel disc, preventing the valve from closing fully.

The non-clogging and ability to withstand abrasive media features of Pinch Valves makes them the best abrasion resistant valves.

Applications for Abrasion Resistant Valves

There are many industries and applications where an abrasion resistant valve may be required, if the media passing through the valve is coarse, dry, sharp or passing through at a high pressure or vacuum.. Some of these examples are listed below. To see more, visit pinch valve applications.

- Food – sugar, flour, corn, oil based products, chocolate.

- Steel shot

- Sand blasting

- Building & Construction – gravel, sand, cement, concrete, aggregates.

- Clay powders – china glaze, silica, bentonite, manganese, ball clay, carbonates etc.

- Chemicals

- Pharmaceutical

- Sludge