What is a Pinch Valve and How Does it Work?

A Pinch Valve is an economical piece of equipment that works like a tap. It has an on/off function, to shut off, allow or control the flow of any media passing through it. The Pinch Valve is made up of three parts:

- Body / Housing

- Internal rubber sleeve

- End connections

The rubber sleeve inside the body of the valve is the part that closes it. When in the open position, the Pinch Valve has a full and true bore. To close the valve, air pressure is supplied into an air nipple on the outer body, which then travels through into the internal part of the valve, pushing down onto the rubber sleeve which fully collapses and closes tightly. With AKO Pinch Valves, the sleeve folds closed in the same way every time, to ensure a longer working life.

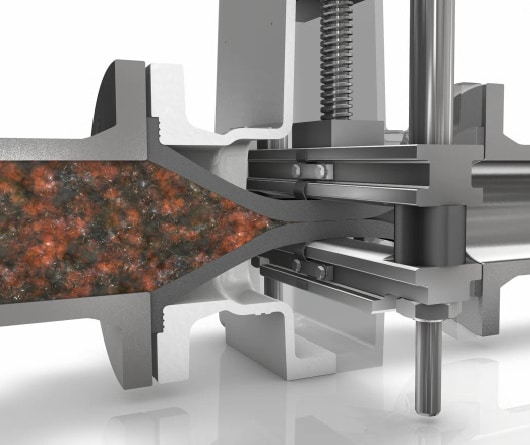

As well as air operated Pinch Valves, mechanical versions are also available. There are two options for controlling the mechanical pinch valves: either with a hand wheel or pneumatically. The manual version simply works by turning a hand wheel to open/close the valve, whereas a pneumatically operated mechanical pinch valve works by compressor bars pulling the sleeve open or pushing together to keep the sleeve closed. This type of valve works on a spring return mechanism and the valve is kept in the normally closed position unless air is supplied to pull the bars apart to open it.

mechanical pinch valve closed with pinch bars

Pinch Valve Vs. Conventional Valves

When referring to conventional types of valves, knife gate sliding valves, butterfly valves, ball valves and diaphragm valves fall into this category. Some engineers do not yet know about the Pinch Valve because it might be new technology to them. However, the Pinch Valve is proven to be the most reliable, cost effective and easy to use valve on the market for some time, in many different applications.

The Pinch Valve does not have any additional parts that will need replacing every so often such as rings, seals and packing etc, giving the Pinch Valve a very good total cost of ownership. Other advantages of the Pinch Valve include:

- Low & easy maintenance

- Low weight

- No clogging or dead spots

- Compact, simple, robust & straight through design

- Very fast opening/closing times

- Less air consumption

- Self cleaning

- Permanent seal with tight shutoff

- Minimal turbulence & friction

- No mechanical parts, and no bearings, seals or packing required.

- Only one replaceable part (elastomer sleeve)

After some research, case studies have been written which show further examples where engineers have changed over from a conventional valve to a Pinch Valve, with much better successful overall performance.

Fit and Forget Pinch Valves

The term ‘fit and forget’ is often referred to when using Pinch Valves, because users can simply install the valve and then leave it alone to do it’s job without the need for any interference. For further information on how to install, operate and maintain Pinch Valves please see technical help.

The lifetime of a Pinch Valve largely depends on the application and how the valve is being operated. For more information please see operating a pinch valve correctly.