A pet food manufacturing company have so far been using aerator pads for 6 months on their hopper passing cereal meal for dog food.

No More Hitting Hoppers with Hammers!

The terms ‘cereal’ and ‘grain’ covers a broad range of different ingredients in this dog food, such as wheat, rice, oats, barley, maize etc.

The problem the company were having is, when the cereal meal mixture becomes moist inside the hopper, it would adhere to the sides and become clogged, leaving a build up of product. The engineering manager expressed that he was having this issue all the time, and had tried external vibrators and even resorted to hitting the exterior of the hopper with a hammer to loosen the clogged cereal meal.

Eventually, he had had enough and resorted to researching alternative solutions when he found AKO UK’s aerator pads.

Aerator Pads used within this application: A730-0478

White food quality Silicon cone shaped pad rated to 200 degrees C. Complete with stainless steel stud, washer and hex nut, and white sealing washer.

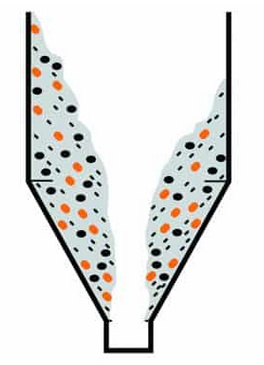

Aerators Prevent Rat-Holing, Caking, Bridging & Arching

The main purpose of a hopper, silo, bin or chute is to store bulk materials when they are not required or in use. However, when one of these vessels accumulates a build up of material in the form of rat-holing, caking, bridging, or arching, a vast majority of that space inside the vessel is not being used with the material ‘stuck’ there.

If the above mentioned issues become severe enough, production can come to a complete stop because of the flow problems. Changes in process conditions, raw materials, or weather can all have an effect on material flow, and even small amounts of accumulation can grow into a serious blockage.

Beyond moisture content, there are many causes of raw material buildup on vessel walls. Some metals contain naturally occurring magnetic properties. Nearly 90 percent of the earth’s crust contains silica, and the sharp crystalline structure can contribute to buildup. Other factors can include the surface friction of the silo walls, the shape of the vessel, the angle of the slope, and the size of the material being loaded.

The solution for preventing rat-holing, caking, bridging, and arching problems does not have to be any large expensive cleaning machinery. Aerator pads are a reliable, cost effective solution that will have your hoppers flowing freely again in no time.

User Experience & Satisfaction with Aerator Pads for Pet Food

The temperature of the cereal meal pet food passing through this hopper is ambient, and flows through naturally with gravity pressure. There are four white food quality aerator pads fitted to the inside of a cylindrical hopper, approx 500mm apart.

There are a total of 8 fills/empties per day. 30Psi is fed to the aerators, which is all it needs to loosen the clogged cereal meal from the inner edges of the hopper, freeing up the flow.

The company decided to use aerator pads for pet food to help with this issue because of the ease and low cost of the products. Their overall satisfaction with the vibrating aerator pads is high, and there will be potential for more aerators fitted around this plant in the future.