Sack Filling with Two Types of Pinch Valves

Here, a company dealing with aggregates are using two different types of Pinch Valves from AKO to aid with a sack filling application.

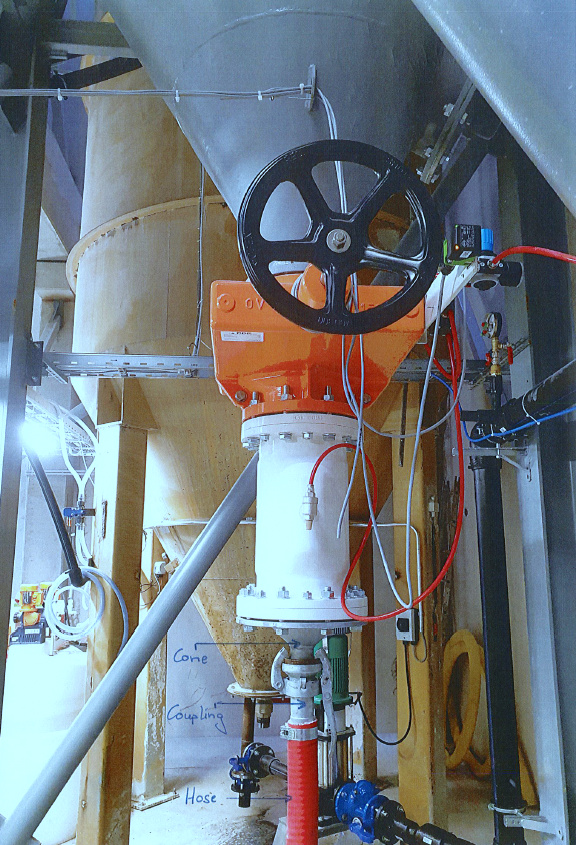

Both valves are situated on the bottom of the hopper which is holding the aggregates. The orange coloured OV type manual pinch valve with a handwheel is being used as a fail safe valve, with the white coloured VF pinch valve set on a timer. The VF type white pinch valve is the secondary option in case the OV pinch valve sleeve fails.

For this particular system, the white VF valve is held closed at 2.5 BAR, holding the gravity fed aggregate from falling through. Both valves are kept closed until the filling process is started, which is when the manual OV valve is opened up using the handwheel and the VF valve is set on a timer to open up, allowing the aggregate to fill sacks as required for 30 seconds. The timer then closes the VF valve again once the bag/sack is full.

The OV valve is then manually closed using the handwheel to act as the fail safe option.