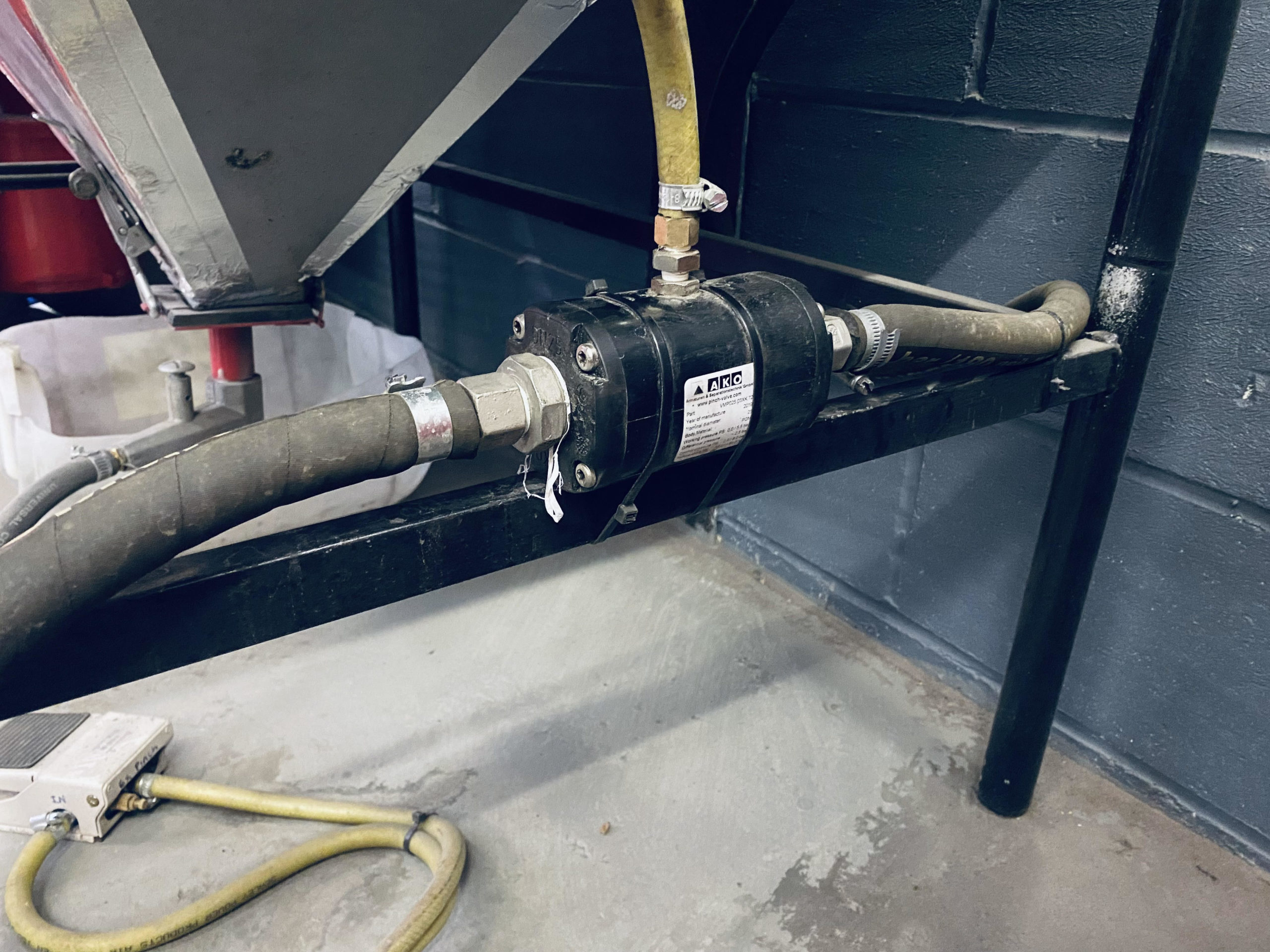

A company dealing with classic vehicle component restoration have a Pinch Valve from AKO installed to the lower frame of their blasting cabinet, controlling the on/off flow function of aluminium oxide.

Application Details

The aluminium oxide is ambient temperature, plus the temperature that the pressure of the media pots adds. The pressure of the aluminium oxide passing through the pinch valve is 80-100 psi. A 3-port foot pedal keeps the valve normally closed, and the valve opens when the pedal is depressed. An air pressure amount of 120 psi or roughly 20 psi above the blasting pressure is applied to fully shut off the pinch valve. Two regulators are used – one for the pinch valve and one for the pressure pot.

Being foot operated allows the operator to use both hands on the component being blasted, rather than one hand pulling the trigger and the other hand holding the part. Using a foot pedal also reduces fatige for the operator.

Pinch Valve used within this application: VMP025.03XK.72

VMP model, air operated, black POM plastic body & BSP threaded ends, natural rubber sleeve.

Valve for Aluminium Oxide Performance

The company decided to use a pinch valve within this system because they needed a way to convert their machine to pedal operation. This is the first pinch valve system this company have used, and to date they have advised AKO that the valve for aluminium oxide has been trouble free so they are very satisfied.

The rubber sleeve has not yet needed to be replaced. However the company have had to upgrade the media hoses attached to the cabinet to a higher spec material because the media wore through the original hose material. To conclude, the natural rubber sleeve inside the pinch valve for aluminium oxide is robust and wear resistant, enabling many cycles to be carried out, and thus creating a long lifetime of the pinch valve.

If the company invest in more machines, then they have advised AKO that they would definitely use more pinch valves for this setup.