A company working on state of the art technologies in the rail sector have developed a new prototype that provides on-board toilet waste recycling.

Providing highly specialised rail depot equipment, the original equipment manufacturer were looking for a suitable valve for train toilet waste to install onto their prototype to direct the liquid flow in the filtration process, through the correct systems. The valves were going to be installed onto rolling stock, and the company were working with a University to develop the product.

The OEM were committed to test the first prototype on a rail vehicle, and then build three further prototypes over the next 12 months for testing.

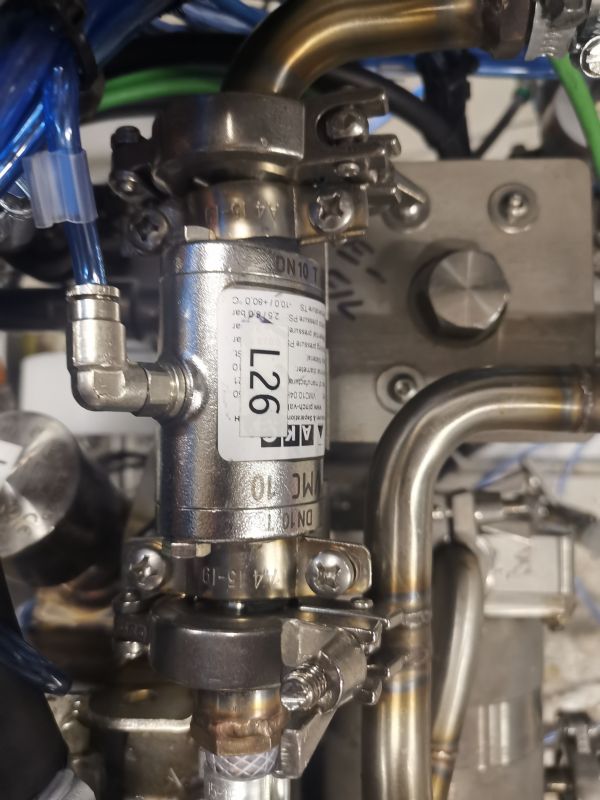

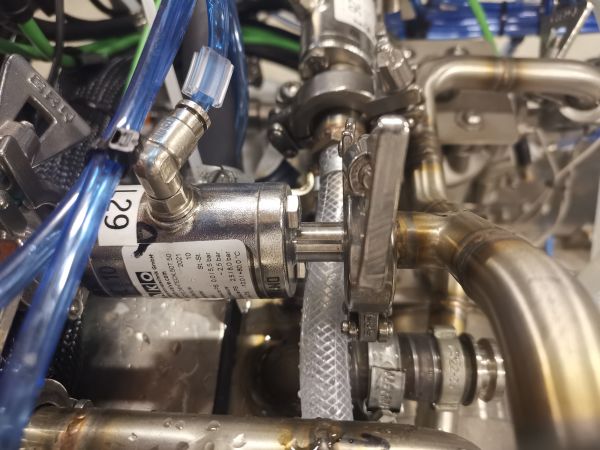

Due to limited space, weight constraints, and needing a minimum maintenance, non-fouling valve solution, the company opted for Pinch Valves from AKO UK which ticked all of the above boxes. They needed 2 normally closed valves and 2 normally open – 4 valves in total per prototype, plus some spares. They wanted to use sanitary hygienic stainless steel pipe work for the liquids sub-system where the valves would be used with tri-clamp fittings.