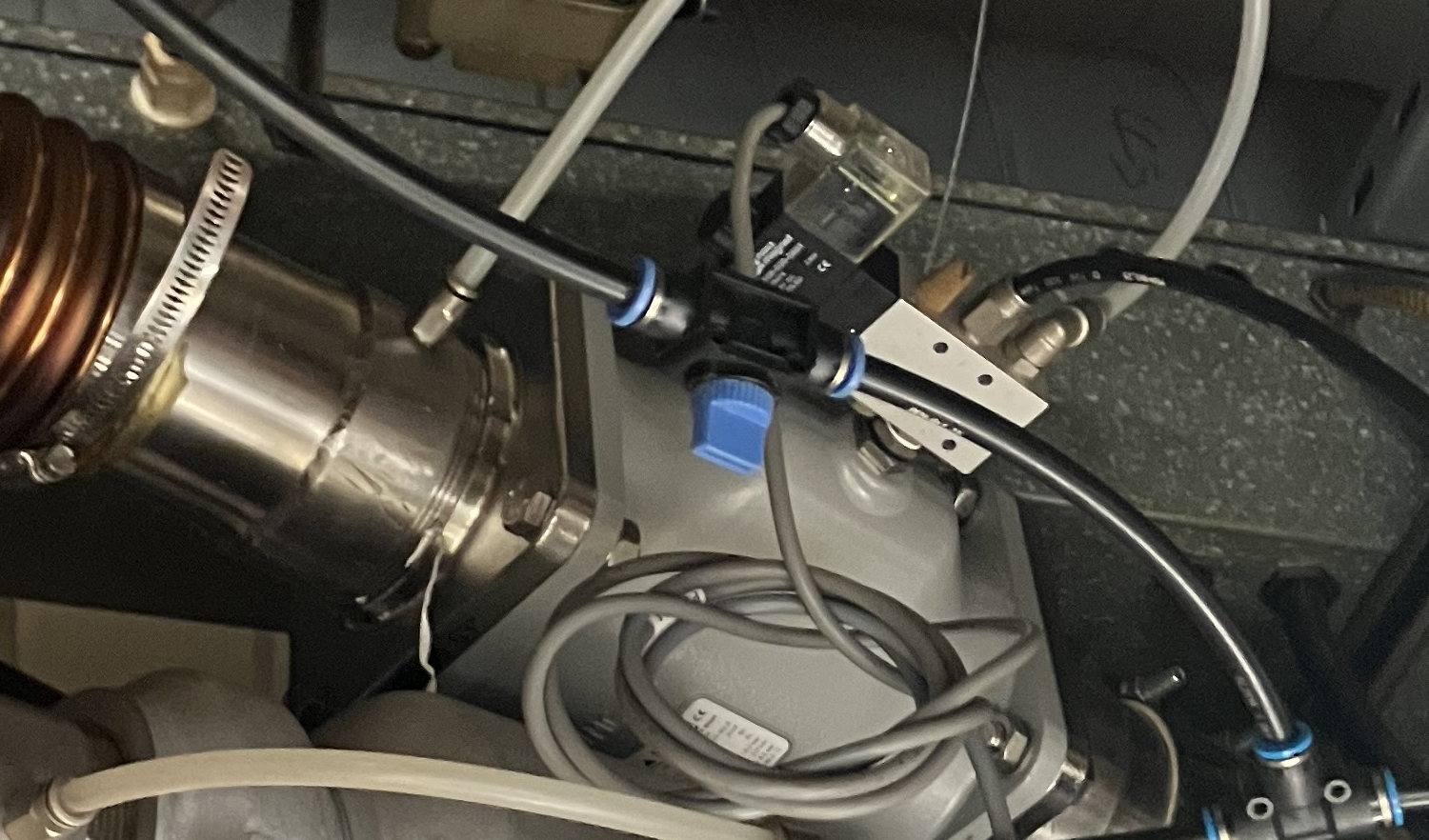

A leading global B2B supplier of tea, coffee and extract ingredients and solutions with operations across four continents are using AKO UK’s Pinch Valves to transfer roasted coffee beans and ground coffee.

There are a total of 9 Pinch Valves on site. The tea and coffee manufacturer were using Pinch Valves by an alternative manufacturer prior to switching to AKO’s products. The Facilities Coordinator for the beverages company told AKO that they had issues with the previous valves fitted as they would not release and return to the open position as they needed them to. Also, the lead time of the original valves was too long. The facilities coordinator said: