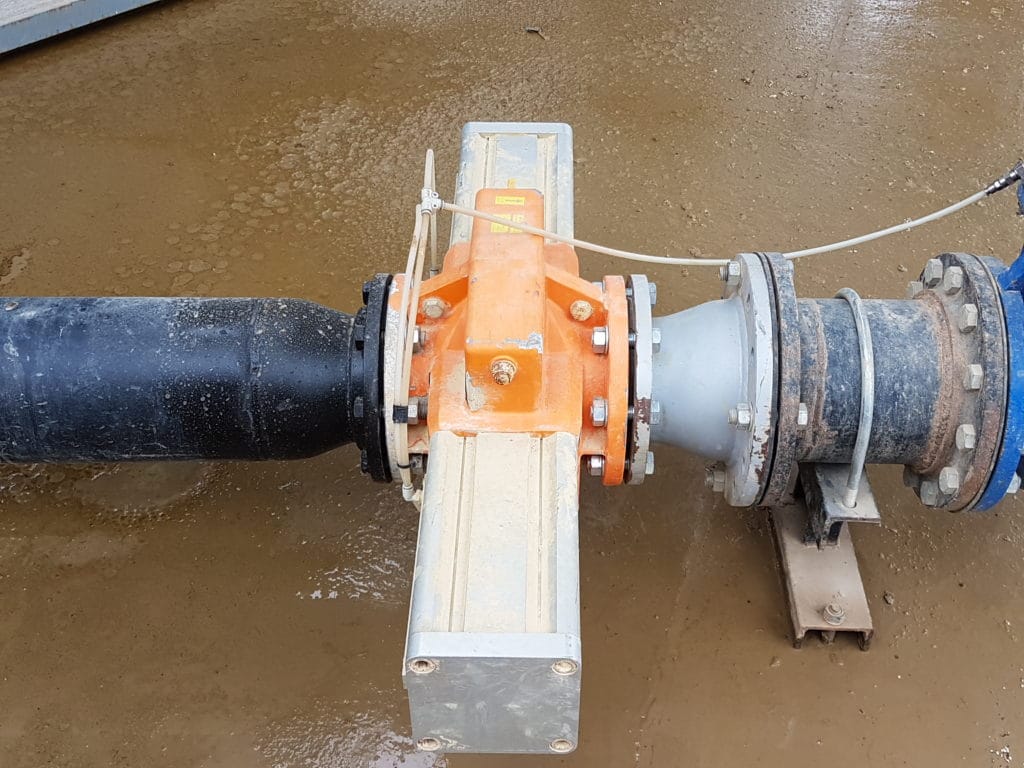

A supplier of quarried limestone products are using a fail safe normally closed Pinch Valve from AKO within their sludge application. The Pinch Valve is size DN200, pictured in orange below.

Pinch Valve used within this application: OV200.03.30.PA2

OV model, air operated, fail safe (normally closed), aluminium body, aluminium flanges PN10/16, natural rubber sleeve.

Sludge is a residual semi-solid by-product left from industrial or refining processes. It is a separated solid suspended in a liquid, typically containing major quantities of water between its solid particles.

Since sludge can be a fairly abrasive media, the Pinch Valve is an ideal solution for efficient flow control, due to its high resilience elastomer sleeve which opens and closes to control the flow. The rubber sleeve does not trap or clog any sludge, unlike gate valves and butterfly valves.

The blue coloured ball valve above is used on a high pressure water injection line. The ball valve only operates if there is a blockage in the pipe and when the pinch valve is fully open. It does not operate when the pinch valve is closed.

Sludge is passed through the Pinch Valve at 1.5 BAR when it is open during the day on this particular plant, using 5-6 BAR pressure to keep the valve for sludge open. The Pinch Valve then holds back water over night, when it is in the closed position.

Media: 75 Micron Sludge & water

Pressure: 1.5 BAR

Cycles performed per hour: 1

Hours per day that Pinch Valve is in use: 12

Amount of Pressure used to keep Pinch Valve Open: 5-6 BAR

It is important that the normally closed air operated OV type Pinch Valve is installed in the normally open position so that the sleeve end/gasket does not leak. When the valve is installed in the normally open position with air applied to it, the sleeve opens flush to the body of the valve and the connecting flange, which allows the sleeve to be in the correct position with no gaps so that it closes with a tight seal in between the two connecting flanges, preventing it from leaking.