A company producing colostomy bags have started to use AKO Pinch Valves within their medical environment. Colostomy bags are used to collect the waste that would normally pass through a human body, by attaching them to one end of the large intestine during surgery.

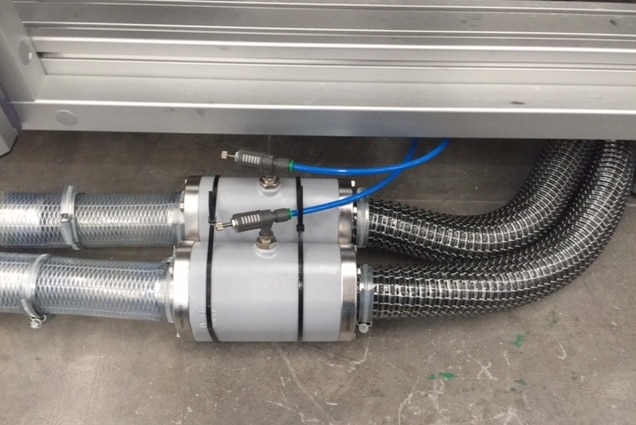

2 of AKO Pinch Valves were trialed successfully within the application, with a further 4 Pinch Valves to follow due to the incredibly reliable response.