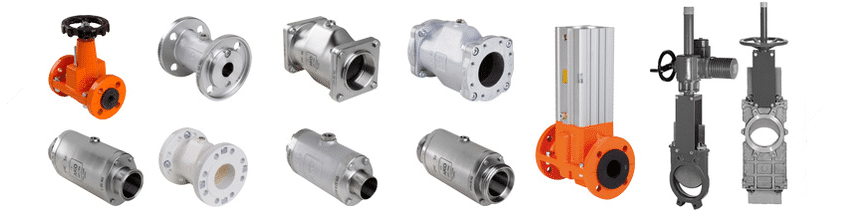

Our economical range of AKO products for flow control solutions are not only cost effective, reliable products for handling abrasive, corrosive and fibrous media with ease. AKO Pinch Valves and other products are also lightweight with easy construction & maintenance and also have unbeatable life times.

AKO Products for Flow Control Solutions:

With a range of available end connections including Tri-Clamp, flanges PN10/16 or ANSI 150, BSP internal thread, RJT threaded spigot, weld-on ends.

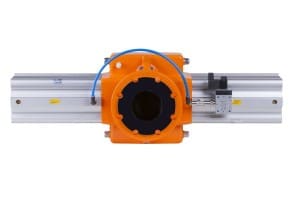

Normally closed fail safe design. Available flanged PN10/16 in aluminium body with spring return actuator.

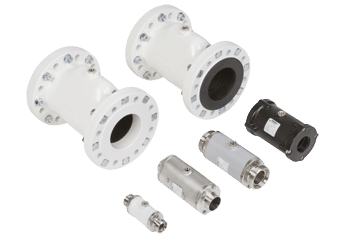

Electro-polished 316 stainless body. Available with tri-clamp fittings, RJT, weld-on ends, BSP internal thread, flanged PN10/16 or ANSI 150.

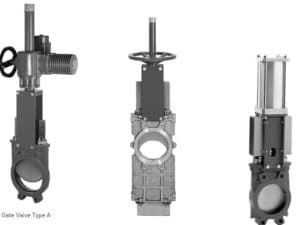

Operated manually with a hand wheel or using air. Normally closed & pinch valves for high performance.

Rated up to 40 BAR working pressure, and available in larger bore sizes up to DN1500.

Available in sizes DN80 & DN100 with tapped hole connections. Used for emptying silo containers and blowing into silos.

Zones 1/21 or 2/22 for all Pinch Valve types. Zones 0 and 20 for stainless steel & POM Pinch Valves only.

Rubber sleeve materials for any application including: Natural Rubber, EPDM, Nitrile, Food Quality FDA Approved, Silicon, Neoprene, Butyl, Viton, Hypalon.

Solenoid valves, pressure switches, safety arrangements, Vacuum systems, quick exhaust valves, proportional control systems, pressure regulators.

The most effective way to protect your pump or motor from over pressure and damage, fitted on a bypass line.

For moving any unwanted build up of clogged media on the inside of silos & hoppers.