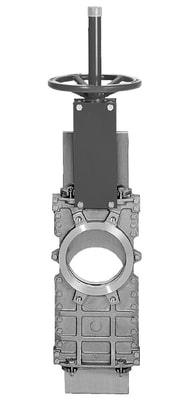

Knife Gate Valve Type A

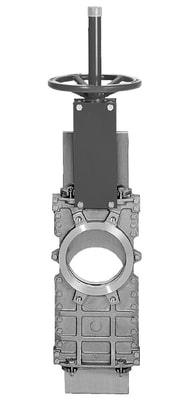

Knife Gate Valve Type B

Knife Gate Valve Type C

Knife Gate Valve Type A

Knife Gate Valve Type B

Knife Gate Valve Type C

For further information on each type of Knife Gate Valve including sizes, design features, actuator types, pressure ratings etc, please refer to the links below to view individual data sheets.

This model knife gate is a uni-directional wafer valve designed for general industrial service applications. The design of the body and seat assures non-clogging shutoff on suspended solids in industries such as:

Pulp and paper

Power plants

Wastewater treatment plants

Chemical plants

Food and Beverage

Bulk handling

Mining etc.

This model knife gate is a wafer valve designed for industrial bulk handling service applications (powdered and granular products). The special design of the body allows for easy passage of the fluid and makes it ideal for use as silo outlet valve. This Knife Gate Valve is widely used in industries such as:

• Power plants

• Food and Beverage

• Chemical plants

• Mining

• etc.

The Knife Gate Valve is normally installed in the reverse position (seat upstream) in order to avoid problems like build-up in valve body, seat wear, difficult closing, etc.

DN 50 to DN 600 (Larger diameters on request)

Type A

DN 50 to DN 250: 10 kg/cm²

DN 300 to DN 400: 6 kg/cm²

DN 450: 5 kg/cm²

DN 500 to DN 600: 4 kg/cm²

DN 700 to DN 1200: 2kg/cm²

Type B

DN 50 to DN 250: 10 kg/cm²

DN 300 to DN 400: 6 kg/cm²

DN 450: 5 kg/cm²

DN 500 to DN 600: 4 kg/cm²

Type C

DN 50 to DN 250: 10 kg/cm² (on seating), 3kg/cm² (off seating)

DN 300 to DN 400: 6 kg/cm² (on seating), 2kg/cm² (off seating)

DN 450: 5 kg/cm² (on seating), 1.5kg/cm² (off seating)

DN 500 to DN 600: 4 kg/cm² (on seating), 1kg/cm² (off seating)